HAHN apprentices take 4th place at German championship for mechatronics engineers

HAHN apprentices take 4th place at German championship for mechatronics engineers

The apprentice team consisting of Valentin Butz and Jonathan Seis from HAHN Automation Group missed the podium at the German championship of mechatronics by a hair’s breadth: they finished fourth, only 0.4% points behind. During the WorldSkills Germany competition at the Festo Learning Center in St. Ingbert from October 17 to 21, the two apprentice mechatronics engineers had to compete against five teams from other companies. The team from Sick AG won the competition. They will now continue training to officially represent Germany at the WorldSkills Championships in September 2024 in Lyon, France.

Every two years, the best future mechatronics engineers meet for the German championship of the WorldSkills Germany organization. From assembly and connection, to maintenance and optimization of a technical system, the participants were expected to complete three to four consecutive tasks on each of the three days of the competition, which they had to master as a team in a specified time.

Fulminant race to catch up

Unfortunately, the first day of competition went anything but well for Valentin and Jonathan. They had to deal with many technical problems and were completely thrown off their game. The two prospective mechatronics engineers were only able to complete a small part of the day’s task and thus scored almost no points. “After the final whistle, they were devastated. It was clear that gold and silver were in all likelihood out of reach and they know what they are actually capable of,” explains Stephan Boos, Trainer at HAHN Automation Group. “It took some good coaxing and motivation from the mental coach and me to get them back on their feet.”

The next day, everything was to go differently. With their heads held high, Valentin and Jonathan started into the competition and everyone saw immediately: the previous day was history. They started a brilliant race to catch up, completed the remaining work from the previous day and mastered the actual day’s task with flying colors. They were able to leave the competition area before time ran out. As a reward they received thunderous applause from all participants and jury members.

The task of the last day of the competition was to optimize the sorting system, which had been assembled and programmed on the first two days, in terms of cycle time and air consumption. “Valentin and Jonathan went all out and were the only team to rebuild their system not only programmatically but also mechanically,” says Boos. “Everyone else focused only on program operations.” And this plan worked: as on the previous day, they dominated the field and were the first team to leave the competition area 36 minutes before the time was up. Thus, the HAHN Team was not only able to score the extra points for the most efficient layout, but also time points.

Since the other participants also performed very well, it was exciting until the award ceremony whether the race to catch up was still enough for a place on the podium. In the end, the HAHN Automation Group Team missed third place by only 0.4% points. “Under these circumstances, this is a terrific result. I am extremely proud of Jonathan and Valentin and they can be too”, Stephan Boos is happy about the performance of his apprentices.

Team performance

At the Regio Cup in July, the two budding mechatronics engineers were still opponents, but at the German championships they competed as a team. After their first experience of competition in the summer, they were both driven by ambition: “For me, it’s exciting to be able to compete with others,” explains Jonathan Seis. “In addition, you gain a lot of experience in a very short time during the competition and also during preparation, which can also help you later in your career.” Valentin Butz can only agree: “My motivation to take part in the German championship was mainly that I wanted to prove my skills and measure myself against other apprentices in my field.”

They traveled to the competition well prepared. In September, they had already gone through a training camp lasting several days. “After that, we knew exactly where we stood and which screws still needed to be tightened,” explains Trainer Stephan Boos. “Together we drew up a training plan and successively tackled one point after another.” Since there were quite a few points, many a weekend fell victim to the training. In addition to the practical training, they also had the opportunity to participate twice in mental coaching with a sports psychologist, which focused, among other things, on coping with tension and excitement.

“The effort was visibly worthwhile, as we saw just after the end of competition days two and three,” states Boos.

Making apprenticeship attractive

The HAHN Automation Group has been a member of the WorldSkills Germany organization for several years, has participated in the competitions more often and has been a regional organizer itself. From the group’s point of view, learning in competition is a perfect complement to the training itself. Only those who face the competition situation out of their own conviction and tackle the required tasks with personal interest prove they have the staying power and often achieve better results.

“In my opinion, the WorldSkills competitions are a highly underestimated tool for also raising the profile of vocational education among the general public and making dual training more attractive to young people,” thinks Stephan Boos. “For this reason, we have also been hosting the Regio Cup for mechatronics and industrial mechanics in Rheinböllen every year since 2021, so that the topic becomes more widespread and many can benefit from this great concept.” And further, “The gathering of different companies also creates a lively exchange among each other, which not only concerns the competitions, but also the training concepts themselves.”

Targeted training of junior staff has a very high priority for the HAHN Automation Group. The trainers understand qualified apprenticeship not only as imparting technical knowledge, but also as supporting young people in their personal and professional development. You can find more information here: Vacancies for apprentices.

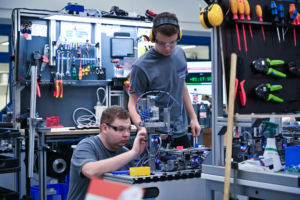

The tasks demanded the highest concentration and tact from Valentin Butz (left) and Jonathan Seis (right) of the HAHN Automation Group.

Happy participants and experts after the competition in St. Ingbert.