AUTOMATION SOLUTIONS FOR EFFICIENT PRODUCTION

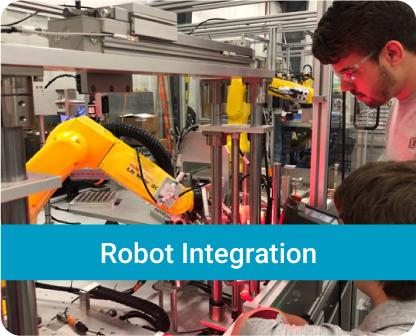

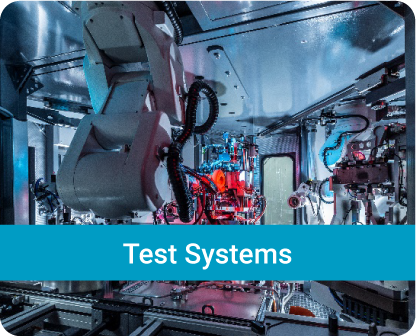

The companies of the HAHN Automation Group develop, build and integrate custom-engineered, high-performance automation and robot solutions for manufacturing companies. With their modular and flexible concepts, the desired degree of automation and the conditions in the production hall can always be individually addressed.

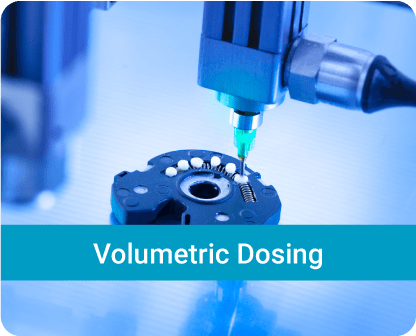

The integrated solutions, digital technologies and robot systems from the HAHN Automation Group support companies on their way to SmartFactory. Whether you deal with systems for high-precision material applications or automation systems with short cycle times: The innovative strength, service orientation and proximity to the customer make the subsidiaries of the HAHN Automation Group long-term partners for the automotive, healthcare, electronics and consumer goods industries.

Solution examples of the HAHN Automation Group Divisions

As special machine builders and integrators, the HAHN Automation Group members are able to deliver semi and fully automatic production lines, tailor-made manufacturing and test systems or standard robots for every individual application. This understanding enables the HAHN Automation Group companies to identify innovations for their customers, allowing them to use and further develop digital technologies in a targeted manner.

With their particularly dense service and partner network, the companies are close to their global customers, who in turn appreciate the contact to local specialists. Competence transfers between the companies ensure that assembly teams are quickly put together for use at the customer sites. Experienced project managers are supported by local experts from the partner and sister companies of the HAHN Automation Group.